Kusarudza yakaringana twist drill bit yepurojekiti yako kunosanganisira kunzwisisa zvinhu zvitatu zvakakosha: zvinhu, kupfeka, uye geometric maitiro. Chimwe nechimwe chezvinhu izvi chinoita basa rakakosha mukuita uye kusimba kweiyo drill bit. Heano kunyatsotarisisa maitiro ekuita sarudzo ine ruzivo.

Material

1. Simbi Inomhanya-mhanya (HSS):

High-Speed Steel (HSS) yave yakakosha mukucheka maturusi kweanopfuura zana, inokosheswa nekushandisa kwayo kwakafara uye kugona. HSS drill bits inozivikanwa nekusiyana-siyana kwayo, ichiita zvakanaka nemaoko ese uye mapuratifomu akatsiga semichina yekudhirowa. Mukana wakakosha weHSS kugona kwayo kurodzazve, kuwedzera hupenyu hurefu hwemabhiti ekudhirowa uye kuita kuti ive sarudzo inodhura yezvishandiso zvelathe zvakare. Uyezve, HSS ine mamakisi akasiyana, imwe neimwe iine akasiyana ekutanga maumbirwo ekuitira kune chaiyo yekucheka zvinodiwa. Izvi zvakasiyana mumagiredhi esimbi zvinowedzera kuchinjika kweHSS, zvichiita kuti ive chinhu chinogoneka uye chakakosha mumabasa akasiyana ekugadzira.

2. Cobalt HSS (HSSE kana HSSCO):

Kuenzaniswa neHSS yechinyakare, Cobalt HSS inoratidza kuoma kwepamusoro uye kutsungirira kwekupisa. Uku kukwidziridzwa muzvivakwa kunotungamira zvakanyanya kunatsiridza abrasion kuramba, zvichiita kuti HSSE drill bits igare yakasimba uye inoshanda. Iko kubatanidzwa kwecobalt muHSSE hakungobatsiri chete mukuwedzera kwayo abrasion kuramba asi zvakare inowedzera hupenyu hwayo hwese. Zvakawanda senge HSS yakajairwa, HSSE mabhiti anochengeta bhenefiti yekurodza zvakare, izvo zvinowedzera hupenyu hwavo hunogona kushandiswa. Kuvapo kwecobalt muHSSE kunoita kuti mabheti aya anyanyokodzera kune mamwe anodiwa ekuchera mabasa uko kusimba uye kuramba abrase kwakakosha.

3. Carbide:

Carbide isimbi matrix inoumbwa, inonyanya kugadzirwa netungsten carbide ine akasiyana mabhaidhi. Iyo inodarika zvakanyanya HSS mukuoma, kupisa kutsungirira, uye abrasion kuramba. Kunyange zvichidhura, maturusi ecarbide anokunda mukurarama uye kumhanya kwekugadzira. Vanoda midziyo yakasarudzika yekurodza zvakare.

Coating

Drill bit coatings anosiyana zvakanyanya uye anosarudzwa zvichienderana nekushandisa. Heino mhedziso muchidimbu kune mamwe majasi akajairwa:

1. Haina kuvharwa (Bright):

Ndirwo ruvara rwakajairika rweHSS drill bits. Yakanakira zvinhu zvakapfava sealuminium alloys uye yakaderera kabhoni simbi, maturusi asina kuvharwa ndiwo anodhura zvakanyanya.

2. Black Oxide Coating:

Inopa mafuta ekuzora uye kudzivirira kupisa pane maturusi asina kuvharwa, inovandudza hupenyu nepamusoro pe50%.

3. Titanium Nitride (TiN) Coating:

Titanium-yakavharwa drill bits inoita zvakanaka mune akawanda maapplication escenario nekuda kweakasarudzika maitiro ekuita. Chekutanga, Iyo inosimudzira kuomarara uye abrasion kuramba kuburikidza nekupfeka, ichibvumira chidimbu kuti chirambe chakapinza panguva yekuchera kuburikidza nezvinhu zvakaomarara, uye kupa hupenyu hwesevhisi hurefu. Aya mabheti anoderedza kukweshera uye kupisa kuvaka, kuwedzera kucheka hunyanzvi uchidzivirira chidimbu kubva pakupisa. Titanium-plated bits inokodzera kushandiswa mune zvakawanda zvinhu, senge simbi isina tsvina, aluminium nehuni, zvichiita kuti zvive zvakanakira mainjiniya uye maapplication emumba. Pamusoro pezvo, mabheti aya anopinza zvinhu nekukurumidza uye kuchena, achipa nzvimbo yekucheka yakanyatsonaka. Nepo titanium-plated drills inogona kudhura kupfuura kudhirowa kwenguva dzose, kugona kwavo kwakanyanya uye hupenyu hurefu hunovaita kudzoka kwakanaka pakudyara kwekushandisa kunoda yakakwira abrasion kuramba uye kucheka chaiko.

4. Aluminium Titanium Nitride (AlTiN) Coating:

Chekutanga, machira eAlTiN anodzivirira kupisa zvakanyanya, achivagonesa kuti vagone kucheka nekumhanya-mhanya uye machining epamusoro-tembiricha alloys. Kechipiri, uku kupfekedza kunonatsiridza zvakanyanya kuramba kweabrasion uye kunowedzera hupenyu hwematurusi, kunyanya kana uchigadzira zvinhu zvakaomarara sesimbi isina tsvina, titanium alloys uye nickel-based alloys. Uye zvakare, iyo AlTiN coating inoderedza kupokana pakati pechibooreso chidiki uye workpiece, kuvandudza machining kunyatsoita uye kubatsira kuwana yakatsetseka yekucheka nzvimbo. Iyo zvakare ine yakanaka oxidation kuramba uye kugadzikana kwemakemikari, ichiigonesa kuchengetedza kushanda munzvimbo dzakaoma dzekushanda. Mune zvese, AlTiN-yakavharidzirwa drills yakanakira yekukurumidza-kumhanya, yakakwirira-chaiyo machining application, uye inonyanya kukodzera kubata zvinhu zvakaoma izvo zvinonetsa kune zvakajairwa drills.

Geometric Features

1. Kureba:

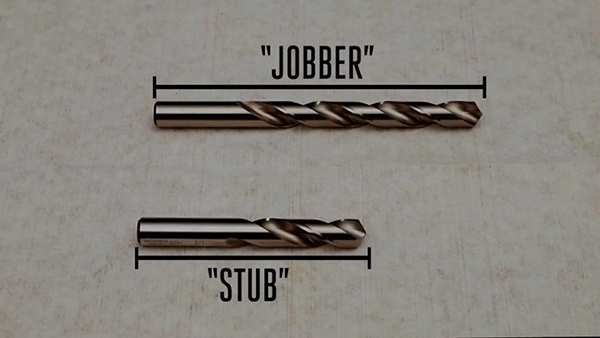

Reshiyo yehurefu kusvika kudhayamita inokanganisa kuoma. Kusarudza chibooreso chine hurefu hwakakwana hwenyere yekubvisa chip uye kuwedzeredza kushoma kunogona kuwedzera kuoma uye hupenyu hwezvishandiso. Kusakwana kwenyere kureba kunogona kukanganisa bhiti. Kune zvakasiyana-siyana zvehurefu zviyero zvekusarudza mumusika. Humwe hurefu hwakajairika ndiJobber, stubby, DIN 340, DIN 338, nezvimwe.

2. Drill Point Angle:

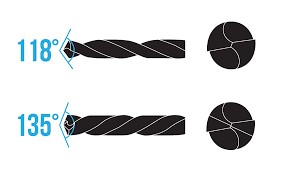

Iyo 118 ° point angle yakajairika kune simbi dzakapfava senge low carbon steel nealuminium. Iyo kazhinji inoshaya kugona kuzvimiririra, inoda gomba rekutyaira. Iyo 135 ° point angle, ine yekuzvimiririra kwayo, inobvisa kudiwa kwegomba rakasiyana repakati, kuchengetedza nguva yakakosha.

Mukupedzisa, kusarudza iyo chaiyo twist drill bit kunosanganisira kuyera zvinodiwa zvechinhu chiri kucherwa, hupenyu hunodiwa uye kuita kweiyo bhiti, uye zvakanangana zvinodikanwa zvepurojekiti yako. Kunzwisisa zvinhu izvi kunovimbisa kuti iwe unosarudza iyo inonyanya kushanda uye inoshanda yekudhiraivha kune zvaunoda.

Nguva yekutumira: Jan-10-2024